Open Optimal Performance With Comprehensive Strapping Machine Service and Upkeep

Strapping machines play an important role in product packaging operations. Their performance directly impacts efficiency and efficiency. Numerous services ignore the relevance of regular service and maintenance. This oversight can bring about boosted downtime and higher fixing costs. Recognizing the key advantages of a proactive upkeep method is vital. As organizations seek to boost their procedures, discovering thorough treatment options comes to be essential. What actions can be required to assure peak efficiency?

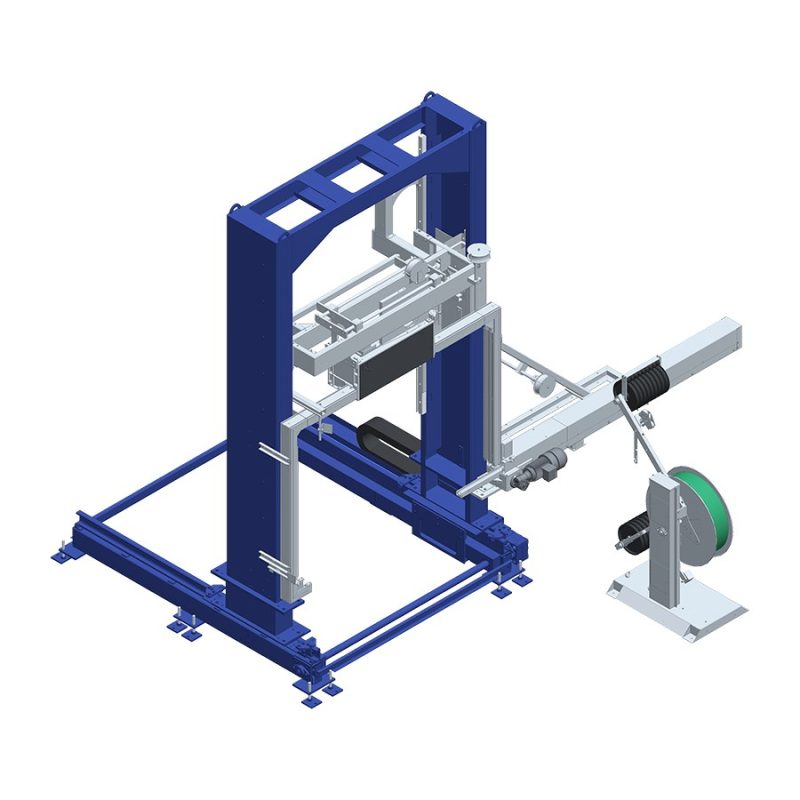

The Significance of Routine Servicing for Strapping Machines

Trick Advantages of a Proactive Maintenance Technique

A proactive upkeep strategy supplies considerable advantages for strapping machines - strapping machine service. By prioritizing regular upkeep, organizations can attain raised tools durability, enhance functional efficiency, and minimize risks linked with downtime. These benefits add to a more dependable and productive product packaging procedure

Increased Equipment Long Life

Applying a proactive maintenance strategy substantially improves the longevity of strapping machines. By routinely servicing and evaluating devices, possible concerns can be determined and attended to prior to they intensify into pricey repair services or failures. This technique lessens deterioration, making certain that all parts function effectively in time. Furthermore, routine maintenance helps maintain the integrity of critical parts, decreasing the likelihood of unexpected failures. Therefore, organizations can extend the functional lifespan of their strapping machines, maximizing their financial investment. Furthermore, properly maintained equipment is much less susceptible to abrupt breakdowns, permitting a much more secure manufacturing environment. Inevitably, a commitment to aggressive maintenance not only protects equipment durability but also fosters integrity and consistency in product packaging procedures.

Improved Operational Performance

They commonly experience considerable improvements in operational efficiency when companies prioritize positive maintenance for strapping machines. This technique warranties that tools runs at peak performance levels, minimizing the possibility of unexpected concerns that interrupt workflow. Frequently scheduled upkeep permits prompt recognition and rectification of potential problems, bring about smoother procedures. Moreover, properly maintained machines call for less power and source consumption, adding to total price savings. By ensuring that strapping machines are consistently in top problem, businesses can raise throughput, boost product high quality, and boost employee productivity. Ultimately, this positive strategy promotes a much more structured procedure, enabling firms to fulfill client needs properly and preserve an one-upmanship in the industry.

Minimized Downtime Risks

Proactive upkeep significantly minimizes the risks of downtime linked with strapping machines. By on a regular basis examining and servicing tools, prospective problems can be recognized and attended to prior to they intensify into crucial failures. This strategy minimizes unexpected break downs, ensuring that manufacturing schedules remain uninterrupted. Furthermore, with a properly maintained strapping device, drivers experience improved reliability and performance, which adds to total operational continuity. Scheduled maintenance also enables the reliable use resources, decreasing the need for emergency repair services that can be time-consuming and pricey. Consequently, organizations gain from improved productivity and an extra streamlined workflow. Eventually, purchasing proactive maintenance leads to a significant reduction in downtime risks, fostering a much more durable production environment.

Common Concerns That Arise From Neglecting Maintenance

Neglecting maintenance on strapping machines can lead to a myriad of issues that ultimately disrupt operations. One common problem is the accumulation of dust and particles, which can cause mechanical parts to jam or wear out prematurely. Furthermore, failure to lubricate moving parts may cause enhanced rubbing, leading to overheating and possible break downs. Misalignment of parts often occurs without routine modifications, leading to poor strapping quality and thrown away materials. In addition, electric parts can degrade if not inspected regularly, resulting in inconsistent performance or total failing. These concerns not only compromise manufacturing effectiveness yet likewise raise repair work prices, highlighting the importance of regular upkeep to ensure peak device performance and long life.

Expert Treatment: Just How Expert Solutions Enhance Tools Durability

Expert solutions play a crucial function in expanding the lifespan of strapping machines with targeted upkeep strategies. strapping machine service. By applying preventative measures, these specialists not only minimize the probability of devices failure but also boost total operational effectiveness. Furthermore, their troubleshooting strategies make it possible for speedy identification and resolution of problems, making certain machines stay in peak problem

Prolonging Equipment Life Expectancy

Preventative Upkeep Perks

Preventative maintenance offers significant advantages for the durability and effectiveness of strapping machines. By implementing routine assessments and servicing, drivers can recognize potential issues before they rise into pricey failures. This proactive method not just prolongs the life-span of the devices but additionally improves its performance, making sure reliable and consistent operation. Furthermore, preventative upkeep minimizes downtime, allowing companies to preserve efficiency while lowering repair work expenses connected with emergency situation break downs. Specialist services supply experience in maintaining perfect equipment problems, using specialized knowledge to address particular wear and tear. Eventually, purchasing preventative upkeep safeguards tools integrity, fosters operational efficiency, and supports a much more sustainable business version, adding to general expense financial savings and raised productivity.

Professional Troubleshooting Strategies

Reliable repairing techniques are necessary for dealing with unforeseen issues that can emerge throughout the operation of strapping machines. Specialists trained in these methods employ methodical techniques to identify and fix issues effectively. They start by assessing mistake codes and maker performance information, which helps browse this site limit possible fault locations. Next, they check elements, such as sensors, motors, and belts, to spot wear or imbalance. Using sophisticated analysis devices, they can identify concerns that might not be promptly visible. In addition, their expertise allows them to recommend rehabilitative activities, making certain minimal downtime. By utilizing these specialist troubleshooting techniques, drivers can enhance devices long life and keep peak performance, ultimately resulting in raised efficiency and reduced operational costs.

Developing a Custom-made Maintenance Set Up

A well-structured maintenance timetable is necessary for making certain the optimal efficiency and longevity of strapping machines. To develop a customized schedule, drivers have to initially analyze the device's usage patterns, identifying high-demand periods and potential tension points. Routine examinations should be scheduled based on manufacturer recommendations, while also taking into consideration actual operational problems. Secret tasks might include cleaning, lubrication, and parts substitute, customized to the specific model and application. In addition, recording upkeep activities enables trend analysis, aiding to forecast future demands and decrease downtime. Engaging with service experts can provide insights into best techniques and essential changes, making sure that the upkeep timetable progresses together with the device's efficiency and functional needs. This aggressive strategy eventually boosts performance and dependability.

Buying Educating for In-House Upkeep Teams

Training programs for in-house upkeep teams play an important duty in optimizing the effectiveness and reliability of strapping machines. By gearing up employee with specialized abilities, organizations can ensure that maintenance and troubleshooting are done properly and without delay. Knowledgeable personnel can identify possible problems prior to they intensify, decreasing downtime and maintenance expenses. In addition, training fosters a deeper understanding of the equipment, enabling teams to execute ideal practices for operation and treatment. This investment not just improves the efficiency of strapping machines however additionally improves group morale and confidence, resulting in an extra aggressive upkeep society. Inevitably, focusing on training will generate significant long-lasting advantages, ensuring peak efficiency and expanding the life-span of strapping tools.

Often Asked Inquiries

Just How Frequently Should Strapping Machines Be Serviced?

Strapping machines must usually be serviced every six months to ensure peak efficiency. Routine maintenance checks assist identify concerns early, prolong the device's life expectancy, and preserve constant strapping high quality and effectiveness in manufacturing procedures.

What Are the Indicators That Upkeep Is Required?

Indicators that upkeep is required consist of uncommon noises, inconsistent strapping top quality, frequent jams, mistake messages on the display, and visible wear on parts (strapping machine service). Resolving these issues without delay can stop more damage and guarantee efficient operation

Can I Execute Upkeep Without Specialist Aid?

Yes, people can do basic maintenance on devices, such as cleaning and evaluating components. Nonetheless, for complicated concerns, expert assistance is advised to guarantee security and correct performance, preventing potential damage or functional failings.

What Parts Generally Call For Replacement During Maintenance?

Throughout servicing, generally changed components consist hop over to these guys of belts, sensors, blades, and springtimes. Normal evaluation of these elements guarantees peak performance and prolongs the lifespan of strapping machines, avoiding unanticipated breakdowns and boosting overall effectiveness.

How Can I Track My Machine's Maintenance Background?

To track a device's maintenance background, one can use logbooks, electronic tracking software, or maintenance administration systems that tape service days, performed tasks, and changed components, making sure detailed oversight of the device's functional problem.

Executing a positive maintenance technique greatly enhances the longevity of strapping machines. Neglecting upkeep on strapping machines can lead to a myriad of problems that inevitably interfere with procedures. Preventative maintenance offers substantial benefits for the longevity and effectiveness of strapping machines. A well-structured upkeep schedule is necessary for ensuring the perfect performance and durability of strapping machines. Training programs for in-house upkeep teams play a necessary function in taking full advantage of the effectiveness and reliability of strapping machines.